What Does the Vertical Speed Indicator Do? Pilot’s Guide

Oct 09, 2024

Understanding the Vertical Speed Indicator

The Vertical Speed Indicator (VSI) is a vital tool for pilots, giving you real time rate of climb or descent information. This is in feet per minute so you can control your aircraft’s vertical movement precisely.

As a differential pressure instrument the VSI measures the difference in pressure between two internal areas. This allows it to give you accurate information for safe flying.

The traditional vertical speed indicator has been a staple in aviation, providing essential data for many years. The Instantaneous Vertical Speed Indicator (IVSI) offers real-time vertical speed data, which is beneficial during dynamic flight situations.

While the VSI averages data over a short period, the IVSI provides near immediate readings, thus enhancing pilot responsiveness to altitude changes.

Also known as the rate of climb indicator, variometer or vertical velocity indicator the VSI goes by many names but does one job in flight. During any flight awareness of vertical speed is part of a pilot’s decision-making process.

The VSI is one of the instruments that make up the “six pack” along with the airspeed indicator, altimeter, attitude indicator, heading indicator and turn coordinator. Each is critical to safe and efficient flight.

Knowing how to read and interpret the VSI is part of a pilot’s skill set. Master the instrument and you can react quickly and accurately and fly with confidence and precision.

Main Components and Operation

To use the Vertical Speed Indicator (VSI) effectively you need to understand its components and how does a Vertical Speed Indicator work.

The vertical speed reading is generated by the collaboration of various parts in the indicator, which helps pilots easily interpret their aircraft's vertical speed.

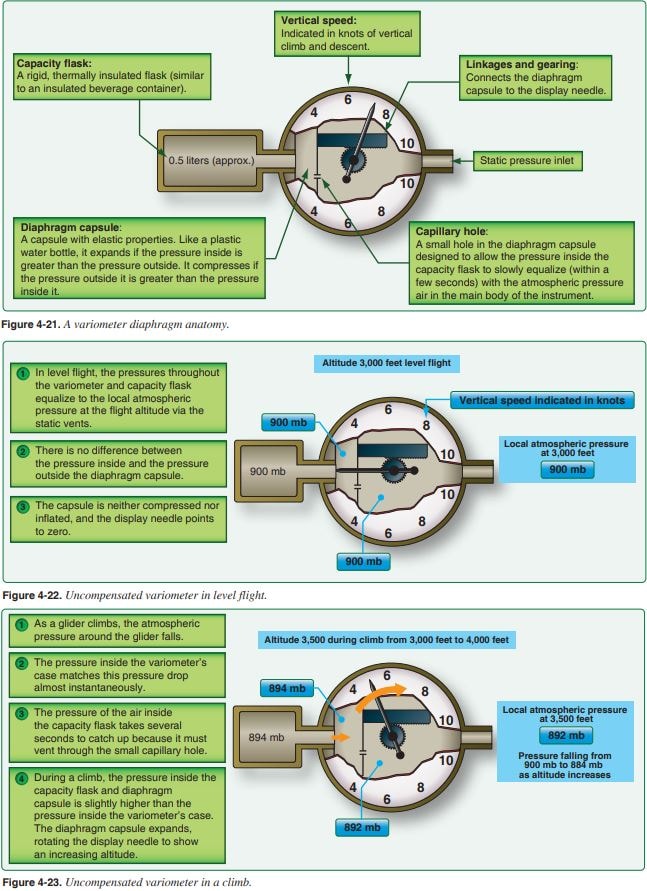

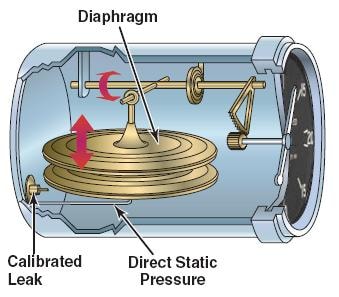

The main components are a diaphragm, a calibrated leak and a static pressure source. Each has a specific job to do to make the instrument work.

The diaphragm is the main component, a flexible metal container. It is directly connected to the static air source of the plane. This is important as it allows the diaphragm to feel the air pressure changes.

The calibrated leak in a vertical speed indicator is another important component. It is a small, precisely engineered hole that connects the casing to the static source. Its job is to restrict the rate of airflow into and out of the instrument, creating a pressure differential that enables the VSI to measure vertical speed.

The static pressure source is important as it provides the air pressure for the diaphragm. This setup allows the VSI to measure vertical speed by feeling the changes in this pressure.

The VSI works because of these components working together. As the aircraft climbs or descends the pressure variation affects the diaphragm. The calibrated leak ensures this happens in a controlled way.

By understanding how these components work together pilots can trust the VSI more. This instrument helps them make informed decisions to fly safe and efficiently.

How Static Pressure Affects VSI Readings

Static Pressure and Climbing Aircraft

As an aircraft climbs, the static pressure decreases in the atmosphere. This change in pressure has a direct impact on the Vertical Speed Indicator (VSI).

Role of the Diaphragm

The diaphragm within the VSI responds to this decrease in static pressure by contracting. Its movement is vital for accurate readings.

Pressure Inside the Casing

Inside the VSI casing, the pressure remains slightly higher due to the calibrated leak. This difference creates a pressure differential.

Movement of the Diaphragm

The pressure differential causes the diaphragm to contract (squeeze down). This action affects the VSI's mechanical components.

Connection to the VSI Needle

The movement of the diaphragm is transferred to the gears, which in turn move the VSI needle upwards. This indicates the aircraft's rate of climb.

Greater Pressure Differential

The larger the pressure differential, the more significant the movement of the needle. This provides crucial information for pilots about their vertical speed.

Pressure Differential and VSI Functionality

The Vertical Speed Indicator (VSI) is a key instrument in the cockpit, telling you how fast you’re climbing or descending. It works on the principle of pressure differences to give you accurate altitude changes.

The heart of the VSI is a calibrated leak, a small intentional hole in the instrument. This allows air to slowly escape the VSI case, maintaining a controlled pressure environment for accuracy.

By allowing the air to escape the calibrated leak creates a pressure difference between the inside and outside of the VSI. This is the pressure differential that makes the instrument work.

As the pressure differential changes the diaphragm moves in the VSI. This movement is transmitted to the mechanical linkages that move the needle on the VSI face. Pilots use the VSI needle to read flight data. Knowing how this simple thing works helps pilots make good decisions and fly safely and efficiently.

Vertical Velocity Indicator vs. Vertical Speed Indicator

The Vertical Velocity Indicator (VVI) also known as the Vertical Speed Indicator (VSI) is an important part of the cockpit to keep pilots informed of their aircraft’s vertical performance.

Although the terms are interchangeable the technology and function are the same, measuring the rate the aircraft is climbing or descending.

This can be critical during key phases of flight such as takeoff, landing and flying through turbulence where accuracy of altitude change can affect overall safety and comfort.

More in depth the VVI/VSI is sensitive to the smallest changes in air pressure which is an indication of the aircraft’s vertical movement.

The calibrated leak in the instrument allows for a comparison between ambient and internal pressure and translates those tiny changes into a movement on the needle on the face.

This mechanical simplicity hides the complexity of what it’s measuring making the VVI/VSI a trusted and solid instrument in the cockpit.

For pilots the VVI/VSI is more than a gauge it’s a tool in their decision making. By giving them real time data on vertical motion they can adjust their control inputs to maintain their desired flight path or react to unexpected changes such as sudden downdrafts or updrafts.

In this way the VVI/VSI helps with precise altitude management and overall safety and efficiency of the flight and proves its worth in aviation.

Common Uses of a Vertical Speed Indicator

A Vertical Speed Indicator (VSI) is a must have in aviation especially during takeoff. It helps pilots see how fast they are climbing as they leave the ground.

When it comes to planning approaches and landings the VSI is also important. It allows pilots to see their descent rate so they can adjust speed and altitude quickly.

In flight the VSI’s main function is to show the rate of climb or descent. It shows how fast the aircraft is changing altitude in feet per minute. This helps pilots control the vertical motion of the aircraft. In flight, the VSI’s main function is to show the rate of climb or descent.

Specifically, the vertical speed indicator shows how fast the aircraft is changing altitude in feet per minute, helping pilots control the vertical motion of the aircraft.

In level flight the VSI should ideally read 0 fpm, that means the aircraft is not climbing or descending. This is key to a smooth cruise and efficient long-range flight.

The VSI is very useful when flying IFR. IFR requires pilots to fly by instruments not visual references and the VSI helps in managing altitude changes without visual references.

Also useful in visual flight but really comes into its own in instrument flying. It’s a must have in instrument flying for safety and efficiency.

Vertical Speed Indicator and Altitude Control

The Vertical Speed Indicator (VSI) is a key instrument for pilots to control altitude. By watching the VSI you can adjust the pitch to maintain a steady rate of climb or descent.

This is especially important during instrument flying where visual references are limited and you are relying on your instruments.

During takeoff the VSI helps you monitor the aircraft performance to make sure it’s climbing at the right rate.

And when planning approaches the VSI gives you the information you need to descend at the right rate to get to pattern altitude from cruise altitude.

Knowing how the VSI relates to altitude is key to safe and smooth flying.

Use the VSI to watch vertical speed and the aircraft will stay on the intended track, and you can make adjustments in real time to stay stable and safe.

Limitations and Considerations

The Vertical Speed Indicator (VSI) is a great tool but has some limitations. Firstly, turbulence can affect the VSI, so be aware that it can be temporarily unreliable.

Changes in pitch attitude will also affect the VSI. Be aware of these during flight to maintain situational awareness. Atmospheric conditions, pressure and temperature will also affect the VSI. Know these and you’ll have more control.

In extreme altitude or airspeed changes the VSI may not be accurate. Take extra care in these situations.

And finally know the difference between trend and rate. The VSI needle may not always show the exact rate of climb or descent, so use other instruments to get the whole picture.

Best Practices for Using a Vertical Speed Indicator

Use the Vertical Speed Indicator (VSI) with other important flight instruments. Using the VSI with the airspeed indicator and altimeter will give you a complete picture of the aircraft.

Instead of looking at specific numbers, use the VSI to monitor trends. This will give you a bigger picture of vertical movement and help you make decisions.

Know the VSI’s limitations. Be aware of how it works in turbulence or rapid altitude changes.

Using the VSI with more tools and techniques will give you situational awareness. Using the VSI as part of a suite of instruments will give you a bigger picture of real time conditions.

To be accurate you need to understand the dynamic nature of flight. Pilots should adjust their use of the VSI according to the conditions.

In the end it’s all about being proactive and informed. Instrument integration and trend monitoring will get you safer and more efficient flying.

Troubleshooting Common Issues

When it comes to the Vertical Speed Indicator (VSI) troubleshooting one of the most common issues is blockages in the pitot tube and static ports.

These blockages can cause inaccurate readings and impact flight safety and efficiency. Pilots should check these components regularly to make sure they are clear and working properly.

Know the potential failures of the pitot-static system. Recognize the signs of malfunction early to address it.

In-flight checks and maintenance schedule can help in early detection and reduce the risk of encountering major problem in-flight.

To minimize instrument errors pilots should take proactive measures. Regular maintenance and cleaning of the pitot-static system can prevent debris from accumulating and causing blockages. This is part of having reliable reading from the VSI.

When the pitot-static system is malfunctioning the VSI won’t give the data pilots rely on.

Know this limitation to make informed flight decision. Pilots should be ready to use alternative instruments and procedures when VSI is not accurate.

Be proactive and know the failures, pilots will have better flight management.

Proactive and informed troubleshooting = safer and more efficient flight = more confident flying.

Advanced Techniques for VSI Use

Instantaneous Vertical Speed Indicators (IVSIs) are innovative tools that offer pilots real-time vertical speed information. They achieve this by utilizing accelerator actuated air pumps, eliminating the lag traditionally associated with standard VSIs.

These advanced IVSIs are equipped with accelerometers along the vertical axis. This configuration allows them to quickly detect changes in altitude, making them highly responsive to the aircraft's movement whether it's ascending or descending.

The rapid response of IVSIs provides pilots with more accurate data, allowing for better decision-making during flights. Applying these timely insights can significantly enhance safety measures and flight efficiency.

Combining IVSI data with other instruments broadens a pilot's understanding of the aircraft's performance. Through this integration, pilots can refine their skills, promoting a more competent and assured flying experience.

Adopting such advanced techniques in using VSIs represents a commitment to ongoing improvement and safety in aviation. By embracing these tools, pilots are better equipped to handle diverse flight scenarios confidently and effectively.

Conclusion

The Vertical Speed Indicator (VSI) is a vital piece of kit in the cockpit, giving you the info you need to fly safe. It helps you understand the aircraft’s vertical movement, which is key to control and navigation.

Knowing how the VSI works, and its limitations is important to get the most out of it. Pilots who know these will make better decisions during flight and be safer.

Best practices are key to getting the most out of the VSI. By following the guidelines you’ll be using it to its full potential and have a more confident flight.

Fixing common VSI problems enables you to get back to flying quickly. This proactive approach reduces interruptions and makes for a smoother flight and better skills.

In general, fixing the VSI helps you hone your flying. That’s a big part of being safe and good at aviation